This report on the analysis of the prehistoric flaked stone collections from archaeological sites CA-MNT-1425 and CA-SLO-692 covers the analytical framework for the study, the specific methods of analysis, the resultant findings, and the interpretation of those findings. These collections were obtained through excavations conducted by Archaeological Consulting in May and July of 1989, respectively (Breschini and Haversat 1989a, 1989b). Appreciation is expressed for the help received from Gary Breschini during this study.

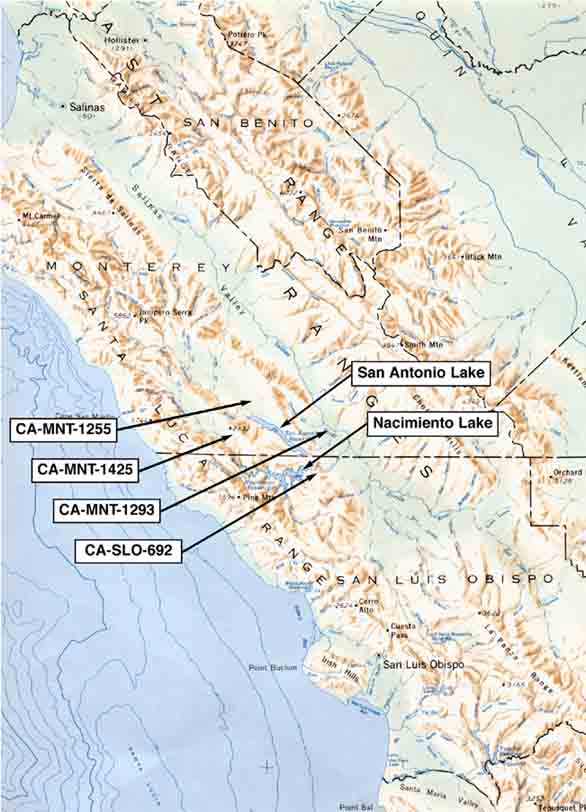

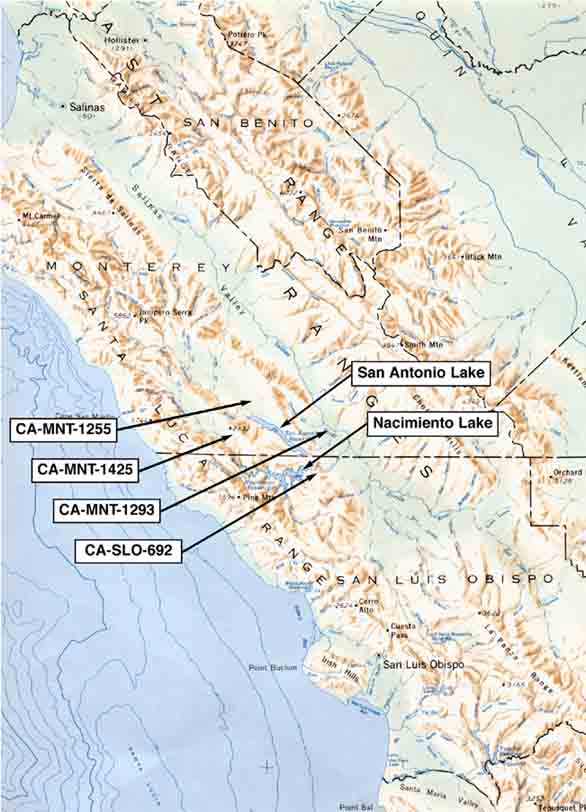

Figure 1. Some of the Sites Discussed in the Text.

Analytical Framework

The research focus of this study was the identification of technological attributes in the flaked stone collection. Two aspects of this identification process were pivotal to the analysis. First, the attributes to be identified needed to have the potential for redundancy. Second, the attributes needed to be assignable to behavioral correlates of high probability.

Identification of redundancy can establish patterns in the flaked stone record. These patterns can be inferred as having resulted from repeatedly occurring activities; specifically attributable to the prehistoric people who manufactured, used, broke, rejuvenated and discarded the materials (Longacre 1974:54-55). However, such forces as erosion, rodents and human activity can intervene to subtly or drastically alter archaeological patterns so that the relationship between past behaviors and the recovered record are not always direct (Schiffer 1976:ix).

Technological attributes to which behavioral correlates can be assigned may, within limits, withstand some intervening pattern distortions since they are literally set in stone. The assignment of behavioral correlates to technological attributes requires that their diagnostic elements can be shown to discriminate specific activities from other similar actions. Further, for these behavioral correlates to be unambiguous, it must be demonstrable in a "contemporary setting" that the agent producing these diagnostic attributes is clearly recognizable (Binford 1983:417-418).

Flintknapping studies have proven, when properly applied, to be the most reliable demonstration indicating the prehistoric agents responsible for the redundant and unambiguous patterns that occur in the prehistoric flaked stone record (Callahan 1979; Crabtree 1972, 1973; Flenniken 1980; Muto 1971). These identified attribute patterns have been found to vary according to the techniques of production and the stages of reduction represented.

However, "For an inference about the past to be of high probability, an additional proposition must be met--that the same relationship obtained in the past as obtained in the present" (Binford 1983:418-418). This caveat has been at the core of criticism about technological analyses that claim to be based on the actual replication of prehistoric behaviors. Even while dissecting the poor logic of such replication claims, Thomas (1986:248) acknowledges that "modern flintknappers can (and should) contribute handily toward archaeological studies of hunter-gathers by defining sets of unambiguous signatures that translate the statics of prehistoric stone tools to the dynamics that produced them."

Actual replication, however, is not required. A reasonable approximation of the past agents that produced the technological attributes is sufficient to allow the development of behavioral correlates that can provide an acceptable level of inference about archaeological collections. This analysis, based on such approximations, must still meet certain considerations required of all good archaeology.

Among these considerations, which stand as interpretative controls applied to this study, are included: 1) a consideration of the nature of the flaked stone sample (its size and manner of selection) in terms of how it influences interpretations; 2) using the technological data to test the flintknapping-derived-concepts that propose the interpretative relationships between technological attributes and past behaviors (rather than just interpreting the data according to those concepts as if it had been assumed in advanced that they were proven to fit the data); and 3) recognizing that prehistoric lithic technology is not completely understood, our current methods of data recovery and analysis insufficient to completely recover, let alone recognize the full range of flaking techniques, stone uses, and other past behaviors that some flaked stone collections represent.

Methodological Framework

The study methods can be described as operating in the two main areas of debitage analysis and artifact analysis. For the debitage analysis, technological, sizing, and material type studies were conducted on the complete collection recovered by each of the two excavations.

The artifact analysis studied all of the formal flaked stone artifacts which included projectile points, other bifaces, edge-modified flakes, cores, and uniface specimens. This area of study identified the raw material types and technological attributes of each specimen in each artifact class.

Technological Debitage Analysis: Debitage has been defined as "residual lithic material resulting from tool manufacture. Useful to determine techniques and for showing technological traits" (Crabtree 1972:58). Debitage includes the flakes, flake fragments, and angular waste that are the by-products of stone tool manufacture. Repeated observations during flintknapping studies have demonstrated that chipping waste reflects the entire manufacturing process. Thus debitage comprises the most informative data set for the understanding of lithic technologies (Crabtree 1972, 1975). Muto has written that "the process of manufacture is more diagnostic than any stage or final product" (1971:93-94).

These studies relied on a tabulation of debitage attributes diagnostic of various flaking techniques and stages of reduction. This is accomplished by maximizing behavioral inferences from the data by applying behavioral correlates to the technological attributes that have been recognized during various flintknapping studies as (Crabtree 1972, 1973; Flenniken 1980; Magne and Pokotylo 1981; Muto 1971).

Debitage attributes recorded by this study included: 1) flakes retaining a biface edge; 2) flakes with cortex; 3) angular waste; 4) flakes with single-facet striking platforms; and 5) flakes with multiple-facet striking platforms that cannot be shown to be biface edge remnants. These flake attributes are discussed below. Three other diagnostic debitage types were ultimately added to this list for a second round of analysis in order to more adequately reflect the organization of the flaked stone technology. These additional flake types included: 1) uniface retouch flakes; 2) ventral flakes; and 3) fragments of plates from cobble sectioning.

The biface edged flake retains a portion of the edge of the biface from which it was struck. This attribute serves as evidence of biface manufacture. The percentage of such pieces in the collection will allow inferences about the intensity of biface production at the site and the stages represented (Rondeau 1982a).

Both cortex flakes and angular waste are often diagnostic of primary reduction by direct free-hand percussion, such as when flakes are manufactured from cores. The absence of attributes indicating any other primary reduction techniques, such as percussion blade production or bipolar percussion, constitutes additional support for the assignment of this technique as the method of primary reduction. These specimen types can also result from other flaking activities such as the beginning stage of thinning and shaping a flake blank into a biface or from core preparation.

Single-facet platform flakes are also often indicative of primary reduction by direct free-hand percussion although these have also been produced during the initial edging and early thinning stages of biface manufacture, especially if the early stages are pursued by flaking only onto the dorsal surface. Another source of this flake type has been the shaping and rejuvenation of unifaces. The multiple-facet platform flake is generally indicative of biface manufacture (Sullivan and Rosen 1985), but they can also be produced during direct free-hand percussion, percussion blade manufacture, and uniface rejuvenation.

Uniface retouch flakes are the result of rejuvenation of unifacial tools, most by percussion retouch (Frison and Bradley 1980:31; Shafer 1970). Frison has identified this debitage as "scraper retouch flakes" (1967, 1968). Three methods of unifacial rejuvenation have been identified by Shafer (1970:481), each producing a different type of uniface retouch flake. These three types are those struck off of the dorsal surface, those struck off the ventral surface, and those which were struck parallel to and removed a linear portion of the uniface edge.

The tabulation of these attributes, as well as the sizing information, was done by material type in order to determine whether flaking techniques, reduction stages, and/or end products differ by material.

Size Class Debitage Analysis: As with the technological attribute analysis, sizing has its methodological basis in flintknapping studies. Debitage produced by biface thinning exhibits a systematic size reduction curve (Patterson 1983:70), with a majority of the pieces under 1 cm in size, the second largest number of flakes in the next larger size, and so on. Patterson (1983) contends that this size reduction curve remains the same regardless of the number of bifaces contributing to the debitage and that it also remains constant for each stage of biface reduction. Various studies (Gunn, Mahula, and Sollberger 1976; Henry, Haynes, and Bradley 1976; Newcomer 1971; Patterson and Sollberger 1978; Stahle and Dunn 1983) have identified this distribution curve even when different sets of size classifications are used and regardless of whether square or round holes are used for size measurements.

In spite of some support for this analytical technique (Patterson 1983), a number of potential problems with size class analysis have been recognized. These include: 1) different techniques to manufacture similar items; 2) the mixing of waste flakes from different flaking techniques; 3) failure of flintknapping to accurate replicate a collection under study; 4) variations in debitage due to raw material differences; and 5) the collection both prehistorically and historically of certain debitage specimens (Stahle and Dunn 1983:94).

The concern by Stahle and Dunn (1983) for technologically mixed collections has proved well founded. It has been the author's experience that the biface debitage size curve for collections dominated by biface manufacturing flakes often masks the presence of other flaking techniques that are numerical minorities in the collection. One example shall suffice. At CA-COL-61 the obsidian was primarily from biface shaping and thinning and the curve agreed with this even though direct-free percussion manufacture of flakes from cores, bipolar percussion reworking of both flakes and bifaces as well as the notching of bifaces were also evident (Rondeau 1990).

Even so, several studies have suggested that primary flake manufacture from cores and similar flaking activities such as the manufacture of crude cobble tools, is sometimes evidenced by a size curve that has its numerical peak in the next to smallest (1 cm) size class. This appears to occur when the given material type was mainly produced by such primary flaking techniques (Dondero 1983; Rondeau and Rondeau 1990).

However, totally erroneous identification of biface debitage collections could occur through the use of only size analysis. Quartz debitage collections from at least three sites in northern California exhibit the "biface" size curve even though they appeared to be almost totally produced by bipolar percussion. This similar appearing size curves are thought to be, in part, a function of the small size of the original pebbles (Rondeau and Rondeau 1989a).

Size analysis isolated from other analytical approaches has not only the potential to mask minority flaking techniques, but also to misidentify entire debitage collections not produced by biface manufacture. Size analysis has also failed to correctly identify an archaeological collection of biface thinning flakes that had the smaller fraction specimens removed by erosional forces (Rondeau 1989). Therefore, interpretation of size class data will be subordinate to the technological findings.

A set of circles plotted on cardboard that measured 1, 2, 3, 4, and 5 cm in diameter were used; the size of each flake from the sample units determined by the circle through which it could not pass, except for those passing through the 1 cm circle. The size classes that resulted were: less than 1 cm, 1, 2, 3, and 4 cm, with the last class being 5 cm and larger.

Formal Artifact Analysis: This portion of the analysis focused on recording morphological and technological attributes of the formal flaked stone artifacts in order to provide data towards the understanding of their manufacture and where appropriate, use and maintenance. The classes of flaked stone artifacts included in this portion of the study were the projectile points, unfinished bifaces, cores, several uniface specimens, and edge-modified flakes.

Biface analysis includes the study of the projectile points. Crabtree simply defined a biface as an "Artifact bearing flake scars on both faces" (1972:38). For this study, both projectile points and unfinished bifacial artifacts will be referred to as bifaces.

At least four main methods of biface manufacture (two or more were often used in combination) as well as a variety of techniques within those methods, were practiced in prehistoric California. The methods of concern here can be modeled as having proceeded through a series of reduction stages involving both bifacial percussion and pressure thinning and shaping of the piece. These stages sometimes occurred at more than one site as the aboriginal flintknappers moved away from the source of the raw material (Rondeau 1982b). This means that a different stage or stages of reduction may be in evidence for each material type represented at any given site.

This method of biface manufacture began with such pieces as a whole cobble, an unmodified flake (commonly referred to as a flake blank), or with a tabular blank quarried from a geologic stratum. Initial edging (creation a bifacial edge) of the piece came first in some cases. In others, a general thinning of the piece came first, striking prepared platforms without an existing bifacial edge.

A number of schemes to characterize the stages of this type of biface manufacturing sequence have been proposed in North America (Callahan 1979; Collins 1975; Crabtree 1973; Frison and Bradley 1980; Holmes 1894; 1897; Muto 1971; Newcomer 1971; Sharrock 1966). Although regional variations in the morphology of unfinished bifaces have been noted in California (Rondeau 1982c), a typology for biface reduction sequences across time and space in California will require a great deal of additional research.

A typology of biface thinning stages based on the degree of biface refinement in outline, cross section and patterning of flakes scars was used to describe the specimens in the collections reported below. The stages used in this reporting are: the early thinning stage; middle thinning stage; late thinning stage; preform stage; and finished stage. The only finished bifacial artifacts recognized in these collections were projectile points.

Projectile points were the most common bifacial finished tool form in California. However, other bifacial artifacts included such items as knives, drills, ceremonial blades, crescents and Stockton Curves. Rejuvenation of projectile points to extended their use-lives occurred. Some specimens were later reshaped into other tool forms such as drills and convex-edged uniface-like tools that often retained the original hafting element. Reworking of older biface pieces meant that they were used as cores from which new flakes were produced. Evidence for such uses and reuses was sought without success in these collections.

Unifaces were defined by Crabtree as an "artifact flaked on one surface only" (1972:97). As the discussion below will indicate, technological studies are making such morphological labels inadequate to the increasingly recognized complexity of past flaked stone tools. Even so, most unifaces are flakes that have been modified initially on the dorsal face, but some exhibit initial or later modification of the ventral surface.

These artifacts are generally divisible from edge modified flakes by the nature of their modification which is more invasive, involving percussion and/or pressure. This flaking often resulted from creation and maintenance of tool edges. This manufacture and maintenance also contributed to various recognized morphological uniface styles.

Unifaces, commonly called scrapers, were widely distributed through time and space and exhibit considerable morphological variation in California. This artifact class, however, is poorly defined in terms of stylistic types, technologies, functions, as well as their temporal and spatial distributions.

Recent observations by the author at several sites elsewhere in Northern California have noted traditionally dorsal flaked unifaces that were subsequently rejuvenated by percussion onto their ventral surfaces. Misidentification of these "bifacial" unifaces as either bifaces or discoidal cores may be common in the literature.

Rejuvenation of this tool type argues for its reuse. A substantial numerical presence of extensively rejuvenated unifaces in a temporally defined component could suggest a pattern of curation. With other lines of similar evidence, such evidence inferring curation could suggest a degree of residential stability.

This uniface analysis was designed to describe the technological characteristics of these tools in order to: 1) indicate their methods of manufacture; 2) identify the types of original forms from which they were made; and 3) evidence for any methods of rejuvenation (Shafer 1970).

Cores have been defined as the nucleus that remains after the removal of flakes (Crabtree 1972). If cores retain evidence of the ways in which those flakes were removed, then it follows that the study of this artifact class may provide information addressing a number of archeological research questions (Rondeau 1979a). Differences in the manner of flake removal are often reflected in the morphology of the cores. Thus, the construction of a typology that reflects techno-morphological core attributes can yield information on stone tool manufacturing and use as well as changes in those activities through time (Rondeau 1987).

Techniques of primary reduction recognized as having most commonly occurred during California prehistory include direct free-hand percussion and bipolar percussion (Rondeau 1987). Variations of these techniques may occur depending on the intent of the flintknapper. Such intents may include the production of flakes to be manufactured into bifaces, unifaces, or flakes to be used-as-produced and the production of cores to be used as tools. It should be remembered that none of these production goals necessarily stand alone, but rather that they may have co-occurred with one another. The manufacture of blade and microblade flakes, although occurring in California (Arnold 1983; Rondeau 1985a; Swartz 1960), appears to be very limited temporally as well as areally.

The core analysis attempted to define the technological and morphological characteristics of the cores by material type, identify the techniques used in core reduction, and any strategies inherent in the use of those techniques. The identification of the technological and morphological core characteristics was then described in terms of core types. These types are based on the presence of such diagnostic attributes as the direction(s) of flake removal, evidence of platform preparation, heat treatment, use damage, and the form and size of the raw material prior to modification.

The edge-modified flake analysis was designed to indicate what may have caused the various forms of edge modification as well as define any patterns of recurring attributes that are likely to have resulted from past patterned behaviors or other recurring forces acting on the flaked stone.

These flakes exhibit one or more modified edges that resulted from such forces as spontaneous retouch, trampling retouch, use retouch, or retouch by pressure and/or percussion flaking. Since casual inspection cannot usually determine whether most of these pieces resulted from use retouch, spontaneous retouch, or trampling retouch, the assignment of edge-modified specimens to a "utilized flake" class is suspect at best. Just as the unsupported assumption that edge-modified flakes are the result of use can be erroneous, so may the assumption that they are mainly the result of trampling.

Since flakes were a readily obtainable source of sharp tool edges their place in any flake stone assemblage needs to be carefully assessed. To provide this assessment, those flake specimens that were observed to retained edge modification were inspected using a Bausch & Lomb binocular microscope at magnifications of up to 30X with direct incandescent light.

Results of the Analyses

CA-SLO-692

Of the 2,381 debitage specimens (Table 1) Monterey Chert was most common (2,014, 84.6%), followed by Franciscan Chert (357, 15.0%), igneous rocks (7, 0.3%), and obsidian (3, 0.1%). Only 9.8% of the Monterey Chert were flakes that retained a biface edge. Although not tabulated for this collection, a high percentage of this chert was fire fractured and the conclusion appears reasonable that the biface edged flake percentage as well as such others as the single-facet platform and the multiple-facet platform percentages are lower than would have been without this post-depositional fire fracturing.

With the collection's current condition, a majority of the angular waste and many of the flake fragments are the result of fire fracturing. Thus it is thought that this heat damage has probably decreased the number of diagnostic flake attributes in the collection. Likewise, the reliability of the sizing information appears to be skewed to an unknown degree through the size reduction of debitage by fire fracturing. While the general size distribution curve thought to indicate biface manufacturing appears to be in evidence, the contribution of thermal fracture to the down-sizing of the collection may have made this more apparent than real. A majority of the specimens at the large end of the scale are attributed to direct free-hand percussion.

Based on the surviving evidence, it appears that a significant portion, probably a majority of the Monterey Chert debitage resulted from percussion biface thinning. Little evidence of bifacial pressure retouch was observed. No evidence of bipolar percussion or percussion blade manufacture was observed. A portion of the collection of Monterey debitage, probably a minority, resulted from direct free-hand percussion manufacturing of flakes from locally available cobbles.

Table 1. Debitage Data for CA-SLO-692.

| | Size (cm) | Attribute |

|---|

| | <1 | 1 | 2 | 3 | 4 | 5 | F | A | B | S | M | C |

| Monterey Chert T = 2,014 |

|---|

| No. | 1,619 | 347 | 27 | 4 | 5 | 0 | 1,523 | 71 | 197 | 108 | 115 | 78 |

| % | 80.4 | 17.2 | 1.9 | 0.2 | 0.3 | 0.0 | 75.6 | 3.5 | 9.8 | 5.4 | 5.7 | 3.9 |

| Franciscan T = 357 |

|---|

| No. | 231 | 93 | 21 | 7 | 5 | 0 | 235 | 26 | 22 | 34 | 40 | 61 |

| % | 64.7 | 26.0 | 5.9 | 2.0 | 1.4 | 0 | 65.8 | 7.3 | 6.2 | 9.5 | 11.2 | 17.1 |

| Igneous Rock T = 7 |

|---|

| No. | 6 | 1 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 1 | 1 | 0 |

| % | 85.8 | 14.3 | 0.0 | 0.0 | 0.0 | 0.0 | 71.4 | 0.0 | 0.0 | 14.3 | 14.3 | 0.0 |

| Obsidian T = 3 |

|---|

| No. | 3 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 1 | 0 |

| % | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 67.7 | 0.0 | 0.0 | 0.0 | 33.3 | 0.0 |

| Legend: |

| <1 cm, 1 cm, etc. = Flake Size Classes | F = Flake Fragment |

| S = Single-Facet Striking Platform | A = Angular Waste |

| B = Biface Edged Striking Platform | C = Cortex |

| M = Multiple-Facet Striking Platform |

How much of the Monterey Chert was locally available is unclear. A small, although uncounted portion of the Monterey Chert appeared to be from a tabular source rather than water rounded rocks. These characteristics, along with its thick golden-cream or gray and white colors, suggested that it was very similar to the Monterey Chert that was procured at the quarry site CA-MNT-1255 (Rondeau 1985b). This quarry lies to the northwest of CA-SLO-692. Traveling on foot, the distance to the quarry appears to be under 15 miles. Whether this chert at CA-SLO-692 is from that quarry or is a more wide spread rock type in the region, remains unknown.

The Franciscan Chert sample was considerably smaller (357). However, due to much less fire fracturing, the technological attribute percentages are felt to be more representative of the technologies that produced the debitage. A lesser percentage of biface edged flakes (6.2%) was found in the Franciscan debitage. Angular waste (7.9%), single-facet platform flakes (9.5%), and cortex (17.1%) were all higher for this chert type indicating that approximately half of the debitage was probably produced by direct free-hand percussion, the other half by percussion biface thinning. No evidence of bifacial pressure flaking, bipolar percussion, or percussion blade manufacture was found in the collection.

The size distribution curve for Franciscan debitage tends to follow the sort of curve that might be attributed to biface manufacture. However, the significantly lower percentage in the smallest size class and higher percentage for the next to smallest class (1 cm) appears to reflect the contribution of direct free-hand percussion to this portion of the debitage collection. Again, most of the larger sized pieces are clearly the result of direct free-hand percussion, apparently from the manufacturing of flakes from cores.

The igneous rock and obsidian categories were too small to offer any interpretations. Although all three obsidian flakes were very small, none were the result of pressure flaking. Two were clearly the result of percussion and the third exhibited a ventral flake remnant for its dorsal face, suggesting that it may have been removed during some sort of modification of a larger obsidian flake.

For the artifact analysis, a total of 19 specimens were studied. These included four projectile points, five unfinished bifaces, five edge modified flakes, three cores, one uniface, and one uniface retouch flake (Table 2). The latter specimen is included here, rather than in the debitage analysis since it retains a variety of attributes informing on the artifact from which it was derived.

The four projectile points were split evenly between Monterey and Franciscan Chert. Two pieces (Cat. Nos. 692-5 and 692-8) were stem fragments which may have come from a fairly large contracting stem point type which might also include the specimen with the base missing (Cat. No. 692-9). The fourth artifact (Cat. No. 692-15) did not suggest a type as it was only an edge fragment. All four retained pressure flake scars. Only the blade element (Cat. No. 692-9) had a large enough surface area to also exhibit percussion thinning flake scars.

The five unfinished bifaces (Cat. Nos. 692-3, 692-10, 692-12, 692-13, and 692-22) were mainly Monterey Chert, with only one specimen (692-10) of Franciscan Chert. Two (692-3 and 692-12), based on their level of refinement in terms of cross section, outline and edge control, as well as flake scar patterns, were placed in the early thinning stage. The reason one was not completed was that there was a failure to successfully thin the piece, while the other was broken during manufacture.

Two others (Cat. Nos. 692-10 and 692-22) were placed in the middle thinning stage. Both were broken during manufacture. The final specimen (Cat. No. 692-13) is placed in the preform stage, although it could probably not have functioned as a crudely formed projectile point. While its still crudely formed nature suggests that it was not finished, its morphology is advanced enough to indicate that it was intended to be one of the larger contracting stem point types. It appears to have been broken during manufacture. Finally, this specimen (Cat. No. 692-13) is of that type of Monterey Chert described above that could have come from a source like that described for CA-MNT-1255.

Only one specimen (Cat. No. 692-14) was initially classed as a uniface. It was a flake of Monterey Chert exhibiting flake scars onto the dorsal face that might be the result of pressure flaking, heavy use or some sort of accidental retouch such as occurs during trampling. Microscopic inspection of this piece found no evidence of use wear, but did identify recent edge damage that accounts for some of the modification, but not necessarily all of it.

The single uniface retouch flake (Cat. No. 692-11) retained evidence of use wear on a portion of its working edge. Subsequent to this, percussion flake scars indicate that rejuvenation of portions of the edge occurred with blows struck against the ventral side of the uniface, removing portions of the tool's modified dorsal face which has been discussed elsewhere as "Retouch Method C" (Shafer 1970:484). Following this rejuvenation work, based on the sequence of the flake scars, at least one flake was removed from the uniface by striking the modified dorsal. This flake was detached from the ventral surface of the uniface. This is Shafer's Retouch Method B. This latter method was also the rejuvenation technique used to remove the specimen under discussion.

Three cores were recovered from the site, two of Monterey Chert (Cat. Nos. 692-7 and 692-19) and one of Franciscan Chert (Cat. No. 692-1). All three were made from cobbles with what appeared to be water worn cortex. The Franciscan specimen was a bifacial core in that flakes were removed from both faces of a single working edge. While this piece had a somewhat chopper-like appearance, no micro-flaking or other readily apparent edge damage was observed to indicate that it had been used.

One of the Monterey Chert cores was multi-directional and the other may have been. No apparent strategies were indicated by these latter two pieces. The sample of cores was too small to allow any general interpretative conclusions.

For the five edge modified flakes (Cat. Nos. 692-16, 692-17, 692-18, 692-20, and 692-21), only one (692-18) retained evidence of use wear. Three specimens were too weathered to allow identification of use induced edge rounding or striations. One of these three and the fifth piece exhibited recent damage that, at a minimum, accounts for at least some of the edge modification.

Table 2. Miscellaneous Artifact Data for CA-SLO-692.

| # | AT | Mat | Cond | OF | FST | CS | L | W | T | WT | MISC |

| 1 | CORE | FC | FF | COB | PE | NA | 5.63 | 4.04 | 3.62 | 81.6 | BIC |

| 3 | B/ET | MC | WO | FB | PE | PC | 7.74 | 4.06 | 2.79 | 76.4 | TF |

| 5 | PP | MC | SF | ? | PR | DI | 1.62 | 1.04 | 0.81 | 1.2 | -

|

| 7 | CORE | MC | FF | COB | PE | NA | 7.36 | 6.46 | 4.90 | 268.3 | MDC |

| 8 | PP | FC | SF | FB | PR | PC | 1.31 | 1.34 | 0.55 | 1.0 | -

|

| 9 | PP | FC | BM | FB | PR,PE | PC | 6.08 | 3.44 | 1.06 | 17.7 | - |

| 10 | B/MT | FC | CF | FB? | PE | LN? | 4.46 | 4.05 | 1.75 | 29.3 | BRK |

| 11 | URF | MC | WO | UNI | PE,MF | NA | 1.97 | 3.45 | 0.94 | 5.9 | REJ.D/V,CR,

ST,SC,R,UW |

| 12 | B/ET | MC | ENF | FB | PE | PC | 4.78 | 4.26 | 1.75 | 30.2 | BRK |

| 13 | B/PF | MC | TM | FB | PE,PR | PC | 6.76 | 3.83 | 1.78 | 41.1 | BRK |

| 14 | UNI | MC | WO | FB | PR?MF | PC | 4.18 | 3.53 | 1.03 | 15.3 | ST,SC,RD |

| 15 | PP | MC | EGF | FB? | PR | PC? | 1.13 | 0.81 | 0.62 | 1.0 | FF? |

| 16 | EMF | MC | FF | PEF | PR | PC | 2.17 | 2.33 | 0.89 | 3.0 | BUR,ST,SC,

R,WE,RD |

| 17 | EMF | MC | BUR? | PEF | MF | PC | 2.31 | 1.11 | 0.45 | 1.2 | SC,R,WE |

| 18 | EMF | FC | WO | PEF | MF | PC | 5.85 | 3.01 | 1.41 | 25.5 | SC,R,UW |

| 19 | CORE | MC | FF? | COB | PE? | NA | 7.51 | 5.20 | 4.79 | 237.5 | MDC? |

| 20 | EMF | MC | FF | PEF | PE | PC | 5.36 | 4.28 | 1.23 | 24.4 | CR,ST,SC,RD |

| 21 | EMF | FC | FF | PEF | MF | PC | 2.65 | 1.81 | 0.75 | 2.5 | CR,ST,SC,

R,WE? |

| 22 | B/MT | MC | ENF | FB | PE | PC | 4.86 | 4.31 | 2.20 | 52.2 | BRK |

Legend:

| # = Catalog Number |

| AT = Artifact Type: CORE = Core; PP = Projectile Point; B/MT = Biface/Middle Thinning Stage; B/PF = Biface/Preform Stage; EMF = Edge Modified Flake; B/ET = Biface/Early Thinning Stage; URF = Uniface Retouch Flake; UNI = Uniface |

| Mat = Material Type: MC = Monterey Chert; FC = Franciscan Chert |

| Cond = Artifact Condition: FF = Fire Fractured; WO Whole; EGF = Edge Fragment; EGM = Edge Missing; SF = Stem Fragment; FF = Flake Fragment; BUR = Burned; BM = Base Missing; CF = Center Fragment; ENF = End Fragment; TM= Tip Missing |

| OF = Original Form: COB = Cobble; FB = Flake Blank; PEF = Percussion Flake; UNI = Uniface |

| FST = Flake Scar Type: PR = Pressure Flake Scars; PE = Percussion Flake Scars; MF = Micro-Flaking |

| CS = Cross Section: NA = Not Applicable; PC = Plano-convex; LN = Lenticular; DI = Diamond |

| L = Length (cm); W = Width (cm); T = Thickness (cm); WT = Weight (g) |

| MISC = Miscellaneous: BIC = Bifacial Core; BUR = Burned; BRK = Manufacturing Break Failure; TF = Manufacturing Thinning Failure; MDC = Multi-Directional Core; REJ.D/V = Rejuvenation on dorsal and ventral faces; FF = Fire Fractured; CR = Crushed Edge (under magnification); ST = Step Scars (under magnification); SC = Scalar Scars (under magnification); R = Edge Rounding (under magnification); UW = Use Wear; RD = Recent Damage; WE = Weathered Edges (under magnification); ? = Unknown or Uncertain |

CA-MNT-1425

The debitage totaled 607 specimens. Of these 598 (98.5%) were Monterey Chert (Table 3) with only a trace of Franciscan Chert (6), igneous rock (2), and an unidentified chert type (1). While Monterey Chert was also the dominant material in this debitage collection, it had an even lower biface edged flake percentage (6.0%) that the other collection. The percentages for single-facet platform (7.7%) and multiple-facet platform flakes (6.4%) as well as for cortex (14.2%) and angular waste (7.2%) were all higher than in the first collection.

It is probably accurate that this difference is the result of about half of the debitage having been produced by direct free-hand percussion manufacture of flakes from cores and the rest by biface manufacture. The extensively fire fractured condition of this chert is a concern. Fully 40% (239) of the Monterey debitage was observed to have suffered thermal damage. Many of the angular waste specimens were fire fractured and may have been core fragments. This is not to suggest that the "cooking" of cores was undertaken, since the fire damage appears to have occurred after these pieces were flaked. Still, the available evidence suggests that most of the biface manufacturing evidence resulted from percussion biface thinning although a number of biface pressure flakes were observed for the Monterey Chert.

Table 3. Debitage Data for CA-MNT-1425.

| | Size (cm) | Attribute |

|---|

| | <1 | 1 | 2 | 3 | 4 | 5 | F | A | B | S | M | C |

| Monterey Chert T = 598 |

|---|

| 452 | 111 | 24 | 9 | 2 | 0 | 435 | 43 | 36 | 46 | 38 | 85 |

| 75.6 | 18.6 | 4.0 | 1.5 | 0.3 | 0.0 | 72.7 | 7.2 | 6.0 | 7.7 | 6.4 | 14.2 |

| Franciscan T = 6 |

|---|

| 3 | 1 | 1 | 0 | 1 | 0 | 4 | 0 | 1 | 0 | 1 | 1 |

| 50.0 | 16.7 | 16.7 | 0.0 | 16.7 | 0.0 | 66.7 | 0.0 | 16.7 | 0.0 | 16.7 | 16.7 |

| Igneous Rock T = 2 |

|---|

| 1 | 1 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| 50.0 | 50.0 | 0.0 | 0.0 | 0.0 | 0.0 | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Unidentified Chert T = 1 |

|---|

| 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| 0.0 | 0.0 | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 100.0 | 0.0 | 100.0 |

| Legend: |

| <1 cm, 1 cm, etc. = Flake Size Classes | F = Flake Fragment |

| S = Single-Facet Striking Platform | A = Angular Waste |

| B = Biface Edged Striking Platform | C = Cortex |

| M = Multiple-Facet Striking Platform |

The size class analysis tended to argue for a majority of the debitage having been produced by biface manufacture, but again, the skewing influence of fire fracturing cannot be adequately controlled. The larger pieces are mainly attributed to direct free-hand percussion manufacture of flakes from cores for the Monterey portion of the debitage collection. Even though CA-MNT-1425 is much closer to the Monterey Chert quarry (CA-MNT-1255) than is CA-SLO-692, debitage of this Monterey Chert variety was not found in the collected sample.

The other debitage materials: Franciscan Chert, igneous rock, and the unidentifiable specimen of chert provided inadequate samples upon which to offer any technological interpretations. The unidentified specimen appeared to be a chert type more common to the coast ranges further inland.

The artifact analysis identified six specimens including two projectile points and possibly a third. Two unfinished bifaces and a single edge modified flake complete the collection.

Table 4. Miscellaneous Artifact Data for CA-MNT-1425.

| # | AT | Mat | Cond | OF | FST | CS | L | W | T | WT | MISC |

| 1 | PP | MC | CSF | TB | PR | PP | 3.99 | 2.83 | 0.74 | 7.3 | ERO?BUR? |

| 3 | B/MT | MC | EGF | FB | PR,PE | PC? | 2.31 | 3.15 | 0.82 | 7.2 | BRK? |

| 5 | B/PF | MC | EGM | TB | PE | PP | 7.90 | 4.76 | 1.44 | 51.8 | BRK |

| 6 | PP | FC | SF | ? | PR | LN | 2.08 | 1.49 | 0.88 | 2.8 | - |

| 8 | EMF | MC | FF | PEF | PR?PE | R | 4.88 | 3.52 | 2.35 | 29.1 | BLFS,ST |

| RA1-1 | PP? | MC | EGF | FB? | PR | PC? | 0.53 | 1.15 | 0.44 | 0.6 | - |

Legend:

| # = Catalog Number |

| AT = Artifact Type:

PP = Projectile Point; B/MT = Biface/ Middle Thinning Stage; B/PF = Biface/ Preform Stage; EMF = Edge Modified Flake

|

| Mat = Material Type: MC = Monterey Chert; FC = Franciscan Chert |

| Cond = Artifact Condition: CSF = Contracting Stem Fragment; EGF = Edge Fragment; EGM = Edge Missing; SF = Stem Fragment; FF = Flake Fragment |

| OF = Original Form: TB = Tabular Blank; FB = Flake Blank; PEF = Percussion Flake |

| FST = Flake Scar Type: PR = Pressure Flake Scars; PE = Percussion Flake Scars |

| CS = Cross Section: PP = Plano-plano; PC = Plano-convex; LN = Lenticular; IR = Irregular |

| L = Length (cm); W = Width (cm); T = Thickness (cm); WT = Weight (g) |

| MISC = Miscellaneous: ERO = Edge Retouch Only; BUR = Burned; BRK = Manufacturing Break Failure; BLFS = Burin Like Flake Scars; ST = Micro Step Scars; ? = Unknown or Uncertain |

The two projectile points were both stem fragments. One of of Franciscan and the other Monterey Chert. The Monterey piece may be part of a contracting stem point. It was manufactured only by pressure edge retouch to the margins of the flake blank. The Franciscan stem fragment may be from a leaf shaped point. The third piece, the possible point specimen, is questionable since it is only a tiny edge fragment. It is Monterey Chert. All specimens retained pressure flaking evidence, but no percussion flake scars were observed.

The two unfinished bifaces were both Monterey Chert. Both appeared to have broken during manufacture although thinning failure evidence was also observed for Cat. No. 1425-5. One is an edge fragment (Cat. No. 1425-3) and other has an edge missing (Cat #5). The former broke in the preform stage and the latter was in the middle thinning stage. Both retain percussion flake scars, although the preform also has evidence of pressure flaking. The middle thinning stage specimen (Cat. No. 1425-5) appears to be a type of Monterey Chert that could have come from CA-MNT-1255.

The edge modified flake is of Monterey Chert. It has several burin-like flake scars running up an arris from a projection. Under microscopic inspection, however, no evidence of use wear was found.

Discussion

Two aspects of the chert in these collections deserves some further discussion. One aspect is the propensity for the Monterey to fire fracture more readily than Franciscan Chert. The other aspect is the occurrence of a few pieces of Monterey Chert that may have come from a prehistoric quarry (CA-MNT-1255) further north.

Thermal Fracture of Monterey Chert: It appears clear in the CA-SLO-692 and CA-MNT-1425 collections, as with some other collections with which this author is familiar: CA-SLO-186 and CA-SLO-187 (Rondeau 1984), CA-SLO-383 (Rondeau 1985c), CA-SLO-99 (Rondeau 1986), CA-MNT-947 and CA-MNT-948 (Rondeau and Rondeau 1987), CA-SLO-7 and CA-SLO-8 (Rondeau and Rondeau 1988) and CA-MNT-108 (Rondeau and Rondeau 1989a) that Monterey Chert is highly susceptible to post-depositional fire fracturing. This tendency is much more pronounced for the Monterey Chert than it is for the Franciscan. This susceptibility to fire fracturing appears to be due to a much higher water content in the Monterey Chert than for other cherts in the region. Due to heating, the water expands more rapidly than can be released by the stone, thus allowing the build up of internal pressures that cause the fracturing (Purdy 1975).

Monterey Chert from the quarry at CA-MNT-1255: The quarry CA-MNT-1255, traveling on foot, is still less than ten miles from CA-MNT-1425 and not too many more from CA-SLO-692. Whether this chert is from that quarry, from a more southern extension of the same geological strata or from a closely allied deposit is beyond the scope of these studies to determine. Extent geological studies of the area (Jennings 1958; Taliaferro 1943) lack the fine grained detail to address these possibilities.

Claiming the prehistoric transport of specific chert varieties within a region of chert sources is not reliable at this time. The adequate identification of the range and location of chert sources within the region as well as an even greater lack of sourcing studies for known sources precludes any validity to such claims. However, it is interesting to note that a review by the author of the point collection from CA-SLO-175 (Abrams 1968) on the northern coast of San Luis Obispo County, has at least one specimen that appears to be made of the same type of Monterey Chert as is found at CA-MNT-1255.

Organization of Lithic Technology: The organization of lithic technology must be seen within the context of the social and adaptive systems of which it was a part. However, for a flaked stone collection to reliably indicate the patterned activities that document how the lithic technology was organized, a sufficient sample of the formal flaked stone artifacts is needed.

The flaked stone from CA-SLO-692 hints at a number of organizational aspects that, if documented with a larger sample, could indicate an inland adaptive strategy during the same time period as the use of the large contracting stem points on the coast, either by peoples that were culturally related to or actually were those who inhabited the coastline during that period.

Such possibilities might be supported through the documentation of the replacement of carried-along tools, especially damaged projectile points. The on-site manufacture of such carry-along tool kits, if further substantiated, could indicate a degree of logistical maintenance and preparation. Such activities might then be shown to be commensurate with a seasonal pattern of upland exploitation by small bands or task specific groups that over time and in aggregate created a substantial archaeological site; or whether the organization of this technology was more akin to a large seasonal base camp or village (of more intense occupation for a shorter time period) from which smaller groups made forays into the surrounding area.

The nature of which of these diverse group types might be suggested in the ways in which they did and did not organize the manufacture and maintenance of their tool kits. Such activities, such as the use and rejuvenation of unifaces might help to shed light on this question. However, further data would be needed to build an interpretation that this flaked stone record actually represents a specific adaptive pose or node on a seasonal round.

In specific for CA-SLO-692, the collection hints at the past activity of retooling of projectile tips by the presence of several point fragments, especially stems. The possible relationship between a reduction sequence of percussion thinned bifaces and the on-site manufacture of replacement points might be verified with a larger sample.

Uniface use at CA-SLO-692 is problematic. The morphology of the one possible specimen did not inspire confidence in its assignment to that artifact class. This assignment was not corroborated by microscopic inspection. The one definite specimen, the uniface retouch flake, may indicate the rejuvenation of a uniface on-site, but one specimen does not provide a basis for substantive interpretation. Further, it does not document the use of such tools at CA-SLO-692.

The debitage, primarily of Monterey Chert, was dominated by percussion biface thinning. Percussion biface thinning is notorious for producing large quantities of debitage for the number of formal artifacts actually produced. While this debitage-intensive tool manufacturing method is abundantly apparent, its degree of importance along side the manufacture and maintenance of other tool types cannot be shown by the debitage analysis, but only through the comparative study of the formal artifact classes.

The limited number of cores suggest a degree of primary reduction, as did the debitage analysis, but its use(s) at the site remain unclear. Certainly flakes were produced, perhaps both as blanks for the manufacture of tools as well as others for immediate use. Of the five edge-modified flakes, only one had use wear. Again, a single specimen does not inspire interpretative confidence. While the bare outlines of a lithic reduction sequence may be suggested, its degree of reliability and certainly its full complexity cannot.

The flaked stone collection from CA-MNT-1425 allows fewer interpretations than that for the site discussed above. The Monterey Chert debitage appeared to be about half from primary reduction by direct free-hand percussion and half from percussion biface thinning. Only two definite point fragments were recovered. Again, these were stem fragments. Several unfinished biface fragments were also recovered along with a single edge-modified flake that failed to exhibit use wear under microscopic inspection. Little in the way of interpretation can be offered except to say that the preliminary indications are that the types of flaked stone technologies used at this site appear to be the same as recognized elsewhere in the region.

Conclusion

Some elements of a model organizing how flaked stone was distributed across the prehistoric landscape were offered as working hypotheses for this region (Rondeau 1985b). In that model it was proposed that local lithic resources, such as those from CA-MNT-1255, would not be heavily or widely distributed. The limited evidence in both of these collections appears to support that prediction, as does the cursory review of projectile points from CA-SLO-175.

The two sites reported here contrast with both previously studied sites CA-MNT-1255 and CA-MNT-1293 (Rondeau 1985b). With the former site being a quarry and the flaked stone from latter largely deriving from a primary reduction workshop of locally available rocks, the debitage collections exhibited little or no evidence of biface manufacturing. Substantial biface manufacturing is indicated at both CA-SLO-692 and CA-MNT-1425.

While there was no evidence for habitation at the quarry, the latter site was tentatively interpreted to have been a temporary camp for a small, perhaps family sized group. Both sites in this report clearly result from much more substantial occupations. Further, since they are apparently somewhat removed from any major sources of flaked stone, they appear, although the collections are limited, to fit the previously proposed model expectation that biface manufacturing failures would become the dominant formal flaked stone artifact at sites somewhat removed from source localities.

It appears that both sites in this report have the potential to suggest substantial refinements to the previously proposed regional lithic model. Does CA-MNT-1425 represent a somewhat limited, seasonally occupied camp aimed towards the procurement of specific resources as may be suggested elsewhere (Breschini and Haversat 1989b)? If so, how does this effect the organization of the flaked stone tool kits? Likewise, if CA-SLO-692 is a major occupation site, possibly even a village (Breschini and Haversat 1989a), how is this reflected in the organization of their lithic technology?

In conclusion, this study has identified a number of intriguing research possibilities, especially for CA-SLO-692, that could substantially enhance our understanding of the prehistory of this region. The study of the organization of lithic technology at these sites has the potential to elucidate the nature of a range of activities, elements of the social system(s) that supported them and ultimately, suggest stronger inferences about the adaptive and mobility strategies of these ancient inhabitants of California.

Bibliography

Abrams, D. 1968. Salvage Investigations at the Little Pico Creek Site: 4-SLO-175. Part 2 in Archaeological Salvage of the Pico Creek and Little Pico Creek Sites. California Division of Beaches and Parks, Sacramento.

Arnold, J.E. 1983. Chumash Economic Specialization: An Analysis of the Quarries and Bladelet Production Villages of the Channel Islands, California. Ph.D. dissertation, University of California, Santa Barbara.

Binford, L.R. 1983. Middle-Range Research and the Role Actualistic Studies. In Working at Archeology, pp. 411-422. Academic Press.

Breschini, G.S., and T. Haversat 1989a. Preliminary Archaeological Report and Archaeological Management Recommendations for CA-SLO-692, in the Nacimiento Lake Area, Northern San Luis Obispo County, California. Ms. on file, Archaeological Consulting, Salinas.

Breschini, G.S., and T. Haversat 1989b. Preliminary Archaeological Report and Cultural Resources Management Plan for the Tierra 1007 Project, near Bryson, Southern Monterey County, California. Ms. on file, Archaeological Consulting, Salinas.

Callahan, E. 1979. The Basics of Biface Knapping in the Eastern Fluted Point Tradition, A Manual for Flintknappers and Lithic Analysts. Archaeology of Eastern North America (7)1.

Collins, Michael B. 1975. Lithic Technology as a Means of Processual Inference. In Lithic Technology: Making and Using Stone Tools, E.H. Swanson, ed. Mouton Publishers, The Hague.

Crabtree, Don E. 1972. An Introduction to Flintworking. Occasional Papers of the Idaho State University Museum 28. Pocatello.

Crabtree, Don E. 973. Experiments in Replicating Hohokam Points. Tebiwa 16:10-45.

Crabtree, Don E. 1975. Comments on Lithic Technology and Experimental Archaeology. In Lithic Technology: Making and Using Stone Tools, E.H. Swanson, ed. Mouton Publishers, The Hague.

Dondero, S.B. 1983. An Analysis of Certain Flaked Stone Artifacts from CA-ELD-426. M.A. Thesis, Department of Anthropology, California State University, Sacramento.

Flenniken, J.J. 1980. Replicative Systems Analysis: A Model applied to the Vein Quartz Artifacts from the Hoko River Site. Ph.D. dissertation, Department of Anthropology, Washington State University.

Frison, G.C. 1967. The Piney Creek Sites, Wyoming. University of Wyoming Publications 32(1, 2, 3).

Frison, G.C. 1968. A Functional Analysis of Certain Chipped Stone Tools. American Antiquity 33(2):149-155.

Frison, G.C. and B.A. Bradley. 1980. Folsom Tools and Technology at the Hanson Site, Wyoming. University of New Mexico Press, Albuquerque.

Gunn, J., R. Mahula, and J. B. Sollberger. 1976. The Sollberger Distribution. La Tierra 3(4):2-8. Southern Texas Archeological Association.

Henry, D. O., C. V. Haynes, and B. Bradley. 1976. Quantitative Variations in Flaked Stone Debitage. Plains Anthropologist 21:57-61.

Holmes, William H. 1894. Natural History of Flaked Stone Implements. In Memoirs of the International Congress of Anthropology, C.S. Wake, ed. Chicago.

Holmes, William H. 1897. Stone Implements of the Potomac-Chesapeake Tidewater Province. Bureau of American Ethnology, Annual Report 1893-1894:13-152.

Jennings, C.W. 1958. San Luis Obispo Sheet. In Geologic Map of California, O.P. Jenkins Edition. Division of Mines, Sacramento.

Longacre, W.A. 1974. Kilinga Pottery Making: Evolution of a Research Design. In Frontiers of Anthropology, M.J. Leaf, ed. Van Nostand Co.

Magne, M. P., and D. Pokotylo. 1981. A Pilot Study in Bifacial Lithic Reduction Sequences. Lithic Technology 10:34-47.

Muto, Guy R. 1971. A Technological Analysis of the Early Stages in the Manufacture of Chipped Stone Implements. M.A. thesis, Department of Anthropology, Idaho State University.

Newcomer, M.H. 1971. Some Quantitative Experiments in Hand-Ax Manufacture. World Archeology 3:85-94.

Patterson, L.W. 1983. The Importance of Flake Size Distribution. Contract Abstracts and CRM Archeology 3:70-72.

Patterson, L. W., and Sollberger. 1978. Replication and Classification of Small Size Lithic Debitage. Plains Anthropologist 23(80):103-112.

Purdy, B.A. 1975. Fractures for the Archaeologist. In Lithic Technology: Making and Using Stone Tools, E.H. Swanson, ed. Mouton Publishers, The Hague.

Rondeau, Michael F. 1979. Behavioral Concepts for the Formation of Core Typologies. Paper presented at the Northern Data Sharing Meeting of the Society for California Archaeology, Sacramento.

Rondeau, Michael F. 1982a. Debitage Analysis: A Basis for Site Characterization. Paper presented at the Annual Meeting of the Society for California Archeology, Sacramento.

Rondeau, Michael F. 1982b. A Lithic Seasonal Round for the Northern Sierra Nevada: A Regional Model. Paper presented at the Eighteenth Biennial Great Basin Anthropological Conference, Reno.

Rondeau, Michael F. 1982c. The Archeology of the Truckee Site, Nevada County, California. Ms. on file, California Department of Food and Agriculture, Sacramento.

Rondeau, Michael F. 1984. An Investigation of Chipped Stone Technology at CA-SLO-186 and CA-SLO-187, San Simeon State Beach, San Luis Obispo County, California. Ms. on file, Department of Parks and Recreation, Sacramento.

Rondeau, Michael F. 1985a. Lithic Techniques of the Tulare Lake Locality. Current Research in the Pleistocene 2:55-56. Orono.

Rondeau, Michael F. 1985b. Lithic Production and Use in the Upper Salinas River Basin, Monterey County, California. Ms. on file, Archaeological Consulting, Salinas.

Rondeau, Michael F. 1985c. Chipping Waste: An Analysis of CA-SLO-383 and a Study of Changes in Flintknapping Behaviors Through Time at San Simeon State Beach, San Luis Obispo County, California. Department of Parks and Recreations, Sacramento.

Rondeau, Michael F. 1986. An Analysis of Flaked Stone from CA-SLO-99, San Luis Obispo, California. In Archaeological Investigations at CA-SLO-99, Pismo Beach, San Luis Obispo County, California, by G.S. Breschini, T. Haversat, and R.P. Hampson. Coyote Press Archives of California Prehistory 26.

Rondeau, Michael F. 1987. Bipolar Reduction in California. In California Lithic Studies 1, G.S. Breschini and T. Haversat, eds. Coyote Press Archives of California Prehistory 11.

Rondeau, Michael F. 1989. Analysis of Debitage and Flaked Stone Artifacts from CA-Alp-104, Appendix A. In An Extended Archaeological Survey Report for the Proposed Road Widening on Highway 4 Near Lake Alpine, Stanislaus National Forest, California by M. F. Rondeau. Ms. on file, California Department of Transportation, Sacramento.

Rondeau, Michael F. 1990. Analysis of Debitage and Edge Modified Flakes from CA-Col-61, Appendix F. In Report on Phase II Archaeological Test Excavation at CA-Col-61, State Route 20, Colusa County, California by D. McGowan. Ms. on file, California Department of Transportation, Sacramento.

Rondeau, M.F., and V.L. Rondeau. 1987. Lithic Analysis of Two Collections from Pine Canyon, West of King City, Monterey County, California. Ms. on file, Archaeological Consulting, Salinas.

Rondeau, M.F., and V.L. Rondeau. 1988. An Analysis of the Flaked Stone Assemblage from CA-SLO-7 and CA-SLO-8, Diablo Canyon, San Luis Obispo County, California. In Archaeological Excavations at CA-SLO-7 and CA-SLO-8, Diablo Canyon, San Luis Obispo County, California, by G.S. Breschini and T. Haversat. Coyote Press Archives of California Prehistory 28.

Rondeau, M.F., and V.L. Rondeau. 1989a. Technological Investigations of Flaked Stone Assemblages from Eight High Sierran Sites, Alpine and Tuolumne Counties, California. Ms. on file, Peak and Associates, Sacramento.

Rondeau, M.F., and V.L. Rondeau. 1989b. An Analysis of the Flaked Stone Assemblage from CA-MNT-108, at Fisherman's Wharf, Monterey, Monterey County, California. In Archaeological Excavations at CA-MNT-108, at Fisherman's Wharf, Monterey, Monterey County, California, by G.S. Breschini and T. Haversat. Coyote Press Archives of California Prehistory 29.

Rondeau, M.F., and V.L. Rondeau. 1990. An Archaeological Study of the Early Flaked Stone Assemblage from Clarks Flat, CA-CAL-S342, Calaveras County, California. Appendix G in An Archeological Data Recovery Project at CA-Cal-342, Clarks Flat, Calaveras County, California, by A.S. Peak and H.L. Crew. Ms. on file, Peak and Associates, Sacramento.

Schiffer, M.B. 1976. Behavioral Archaeology. Academic Press, New York.

Shafer, H.J. 1970. Notes on Uniface Retouch Technology. American Antiquity 35(4):480-487.

Sharrock, F.W. 1966. Prehistoric Occupation Patterns in S.W. Wyoming and Cultural Relationships with the Great Basin and Plains Culture Areas. University of Utah Anthropology Papers 77.

Stahle, D.W., and J.E. Dunn. 1983. An Analysis and Application of the Size Distribution of Waste Flakes from the Manufacture of Bifacial Stone Tools. World Archeology 14(1):84-97.

Sullivan, A.P., III, and K.C. Rosen. 1985. Debitage Analysis and Archeological Interpretation. American Antiquity 50(4):755-779.

Swartz Jr., B.K. 1960. Blade Manufacture in Southern California. American Antiquity 25:405-407.

Taliaferro, N.L. 1943. Bradley-San Miguel District. In Geologic Formations and Economic Development of the Oil and Gas Fields of California. California Division of Mines Bulletin 118. San Francisco.

Thomas, D.H. 1986. Contemporary Hunter-Gatherer Archaeology in America. In American Archaeology: Past and Present, D.J. Meltzer, D.D. Fowler, and J.A. Sabloff, eds., pp. 237-276. Smithsonian Institution Press, Washington, D.C.